A Beginner's Guide to Stitch Types: The Most Common Stitches and Uses in Garment Making

Written by Rachel Blaydes

Have you struggled with determining which stitch to use for your designs? Fashion Index to the rescue! There are several factors to consider when picking which stitches will work best for your garment. We will break these down and demystify how and where you might use the stitches available on your machine.

ISO Terminology: How Stitches are Created

Here is some helpful terminology about the processes that threads go through to create stitches. Intralooping is the passing of a loop of thread from the top of the fabric, within another loop on the bottom of the fabric by the same thread. Interlooping is between two threads, where the bottom thread creates a loop, and the top thread comes down through the fabric and creates a second loop around the bottom thread. Interlacing is when the bottom thread crosses over a loop made by the top thread. This entwining creates two loops that are facing opposite directions.

Understanding ISO Stitch Classifications

Stitches are identified with classifications from the International Organization for Standardization (ISO) that help clarify how stitches are constructed and what the best uses are. Commercial stitches are divided into classes based on complexity, configuration, and type of machine required.

There are six different classifications for stitches used in garment making. Each classification is sectioned into individual stitch types.

Exploring Single Thread Stitches: Types and Function

100 class stitches are also referred to as single thread chain stitches. This class of stitches is produced with a flat bed (lockstitch) sewing machine. This is the most popular type of home sewing machine, and a typical lockstitch machine is capable of creating most class 100 and 300 stitches.

They are made with one or more needle threads and are characterized by the process of intralooping.

Since these types of stitches are made with only one thread, they are rigid, and therefore are not ideal for knit fabric. Due to the construction of the stitch, this class does not perform well under high amounts of stress, additionally they can unravel easily if a thread is broken.

This class is perfect to create temporary stitches or blind hems. The most common stitches are 101, the single thread chainstitch, and 103, the single thread blindstitch. Single thread chain stitches are often used to hold fabric pieces together before a permanent stitch is made. Blindstitches are great for hemming delicate fabric or when you don't want visible stitches at your garment's hemline.

Functional and Decorative Hand Stitches

200 class stitches are primarily hand stitches, and include temporary and permanent stitch types, such as basting stitches or topstitching. Most commonly, topstitching done by hand is created for decorative purposes. They are formed by a single thread that creates one line that is passed from one side of the fabric to the other.

The functional stitches in this class (type 202 and 205) are useful for basting or tacking (temporary hold), and small repairs. There is not a most common stitch in the 200 class, as the use of any of these stitches is dependent on the application and personal comfort with hand stitching.

The exception in this class is type 205, which are produced with a special automatic machine called a pick stitch sewing machine that simulates a running hand stitch.

Understanding Lockstitches: Strengths and Uses

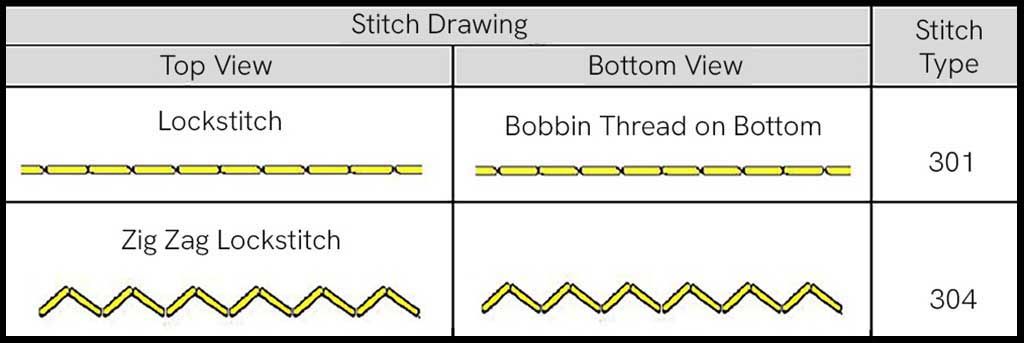

300 class stitches are called lock stitches. This is the most common stitch type that is used in woven garment construction. Lock stitches are made when thread(s) enter through one side of the fabric, and are interlaced with thread(s) from the other side. Interlacing is made by the top thread and bobbin thread.

Overall, this stitch class produces strong, secure, and neat stitches. The disadvantage is that lock stitches don't have stretch, which means the thread could break if under a large amount of tension, making it not ideal for knit fabric. The bobbins will also require changing, so be mindful of how empty your bobbin is before starting your next seam!

Type 301 is the most commonly used stitch in this class due to its simplicity and strength. Type 304, a zig zag stitch, is also a regularly used stitch, and is helpful for reinforcing buttonholes. Zig zag stitches work for sewing stretch fabric if you don't have a special machine, such as a serger (overlock machine).

Pro Tip: When using class 300 stitches, make sure to back stitch both ends of your seam so they don't unravel and undo your hard work!

Multi-Thread Chain Stitches: Looper Thread, Cover Stitches, and Overcast Stitches

400 class stitches are known as multi-thread chain stitches, and are the second most common stitch class for woven garment construction. Class 400 chain stitches are the most secure version of a chain stitch, as it incorporates a looper thread. The looper thread on the underside of the fabric creates a loop, then the thread on top comes through the fabric, and creates a loop of its own.

Cover Stitches are more decorative stitches that are often used on hemlines. They consist of two parallel straight stitches on top, and an overcast stitch on the bottom. Overcast stitches are formed when the thread wraps around the edge of seams or fabric.

This category includes multi-thread chain stitches and cover stitches. Cover stitches can only be produced with a cover stitch sewing machine. Most cover stitch machines are capable of one, two, or three needle stitches. These machines cannot back stitch and seams can be easily unraveled if the threads are cut or damaged. This can be minimized by sewing over the ends or using a bar tack stitch.

This class works very well with knit garments because of the stitch thread formations. Common stitch types for this class are 401, 406, and 407. Type 401 is more durable than type 101 chain stitches and is used for pant hemlines on denim fabric. Types 406 and 407 are helpful for finishing raw hemlines with an aesthetically pleasing stitch. A two-needle coverstitch is suitable for lighter fabrics and a three-needle coverstitch works best on heavier fabrics.

Overlock Chain Stitches: Multiple Threads and Applications

500 class stitches are overedge chain stitches, but are more commonly referred to as overlock stitches. They are created on a specialized sewing machine called a serger using between 2- 5 different threads at once, depending on the machine's capabilities. Sergers do not use bobbins and feed two layers of fabric more evenly than lockstitch machines can. At least one thread set encases the fabric's raw edge and most machines that can do this stitch come with a trimming knife to ensure there is a straight edge to the fabric.

Stitches in this class are ideal to prevent fraying of your fabric and are durable. This class, especially type 504, is most often used for knitwear because these stitches allow for stretch. Type 514 is a great stitch for heavy fabrics, and is commonly used for leg seams on denim.

Pro Tip: Add a temporary stitch or pin your fabric together before using your serger. Overlock stitches are challenging and time-consuming to undo!

Safety Stitches: Two Classes in One, Benefits, and Uses

Combination Stitches are a combination of construction and finishing seams, created simultaneously by a serger and do not require further reinforcement. Because combination stitches are used for secure garment construction, they do not allow for much stretch. These stitches can be used on a variety of fabrics and garments, and are most commonly seen on the inside seams of both woven and stretch woven pants. Despite not having much stretch, these stitches also work well for knits because the overedge threads prevent fraying.

Stitch type 515 is a 4 thread safety stitch that consists of both a single needle chainstitch (type 401) and a 2 thread overedge stitch (type 503). Stitch type 516 is a 5 thread full safety stitch that contains both a single needle chainstitch (type 401) and a 3 thread overedge stitch (type 504). Type 516 is much more common for creating seams for pant legs because it is more durable than type 515. In seams using safety stitches, the type 401 stitch bears the brunt of the stress that the seam endures, and the overedge stitch covers the edge of the fabric and provides additional security.

Flatlock Stitches: What Are Covering Threads, Flat Seams, and Overlapping Edges?

600 class stitches are known as covering chain stitches, but are also referred to as flat seam or flatlock stitches. Stitches in this class are more advanced than 400 class cover stitches because they utilize a top covering thread that is woven between the two needle threads, making them more durable. They are created using between 3 and 9 threads, depending on the stitch type, and use two needles, a looper, and a spreader. The needle loops are interlocked on the top side by the covering thread, and interlooped on the bottom by the looper thread.

This stitch class is commonly used for knits, laces, and lingerie because it is used to join two overlapping edges. A flat seam is created when the “wrong” side of one fabric edge is laid over the “right” side of another fabric edge and stitched. Class 600 stitches are regularly used for activewear to create flat seams that don't irritate the wearer's skin. Type 602 is the most common stitch in this class, and is used to attach lace and elastic to knit fabrics and hem t-shirts.

Now you have a basic understanding of stitch types and their applications! The kind of fabric that you are using and the garment's intended functionality are the main factors when picking stitches. Let your fabric, garment, and design aesthetic guide your decision making process.