Thread Characteristics: From Fibers to Finishes

Written by Rachel Blaydes

Choosing the correct thread for your sewing project will help your final product look the way that you envisioned it. There is a lot to consider when picking thread for your project, including fiber content, types of thread, weight, and finishes. Read on as we introduce the different aspects that make up thread types, and how to understand which thread is best suited for your garment.

Once you have identified which stitch type(s) will be best suited for your design, you can move on to choosing thread types. If you haven't chosen your stitch types, check out our article about them HERE! Your fabric type and weight will play an important role in determining the characteristics needed in your project.

Understanding Fiber Content

The fiber content of your sewing thread can have a major impact on the functionality and durability of your seams. Thread is constructed from cellulose, protein, synthetic, and/or semi-synthetic fibers. A good rule of thumb is to use thread that matches the fiber contents of the fabric you are using.

There is also all-purpose thread that can work for a wide variety of applications. All-purpose thread is usually made from polyester or cotton wrapped polyester and is compatible with the majority of light to medium weight fabrics. There's a wide variety of options available for industrial use, however most sewing threads for the home-sewer are based on synthetic materials such as polyester or nylon, which have largely replaced natural fibers like cotton and linen as the materials of choice for sewing thread. Threads for hand sewing are still predominantly made out of cotton.

Cellulose fibers are plant-based natural fibers such as cotton, and flax which is used to make linen. These fibers are hydrophilic, meaning they will absorb water, and are the most breathable. They have a high tensile strength, which allows them to bear a large amount of stress before breaking or stretching. Cellulose fibers are also eco-friendly and biodegradable, depending on any coating added.

Protein fibers are animal-based natural fibers such as silk and wool. Animal-based fibers are also hydrophilic, but are more resistant to wrinkling than cellulose fibers. They are naturally antibacterial. Uncoated fibers made from proteins are also eco-friendly and biodegradable.

Synthetic fibers are man-made and include polyester and nylon. Synthetics are naturally hydrophobic, which means that they repel water. This makes them a good choice for moisture-wicking athletic wear or waterproof clothing. Man made fibers have more stretch and are more durable than natural fibers. Because these threads are petroleum-based, they are not biodegradable.

The only Semi-synthetic fiber is rayon. It starts off as a cellulose fiber, usually wood pulp, which is then purified and soaked in a sodium hydroxide solution. The fiber sheets are then dried, shredded, and dissolved in other chemicals. The product is filtered again, and given a chemical bath to allow the fibers to be turned into filaments.

Because the base of this fiber is cellulosic, rayon is hydrophilic and is often a substitute for cotton threads. Due to the chemical-intensive process, creating this fiber has a negative environmental impact and can be dangerous to workers' health in the process. A more eco-friendly version of rayon is lyocell, which is made using a closed-loop system that ensures that almost all of the solvent used to make the thread gets reused. Lyocell is also made with less harsh chemicals than traditional rayon, and is less resource intensive to produce.

What Are The Types of Spun Thread?

Spun threads are composed of either staple or filament fibers. Multiple threads twisted together make a ply. Staple fibers are made from natural fibers that are bound together by twisting to create thread and are typically 2 - 46 centimeters, about 0.8 - 18 inches, in length. All natural fibers fall into the category of 'staple' except for silk, which is the only natural filament fiber. A monofilament is a single continuous strand of extended length. Filament threads consist of two or three monofilaments spun together. These are called 2-ply or 3-ply threads.

- Ply thread: Two or more single threads or filaments twisted together

- Corded thread: At least two plys that are spun together to make a thicker, stronger thread; commonly used in leather work and shoemaking

- Corespun thread: An inner core composed of one or more threads, wrapped in an outer sheath, commonly cotton or polyester

- Smooth filament thread: Two or more monofilaments that are twisted together

- Textured filament threads: Polyester threads that are manipulated to have irregularities

Plied threads always have either a Z-twist or S-twist. Z-twist threads are twisted to the left, and are the most common type of twist that is used commercially. They work on both home and industrial sewing machines. The left direction of the twist keeps the thread from unraveling as it travels through the machine. Whereas S-twist threads are twisted to the right, and are primarily used on the right side of machines that use double needles (or hand stitching), and loosen as you sew. Threads typically undergo an S-twist and then are twisted in a Z-twist as a ply.

Understanding Thread Weight: Fixed Weight vs Fixed Length Systems

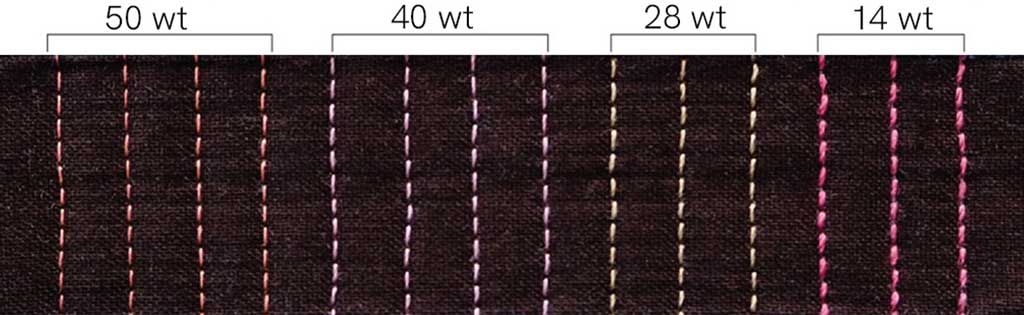

There are two different systems used to measure threads, fixed weight or length. The fixed weight system is the most common for sewing threads. Thread weight refers to the thickness or heaviness and will be noted on the spool. The thicker your thread, the more the stitches will be seen.

In the fixed weight system, the weight is a set number and the length of the thread is the measurement taken. In this system, a higher number indicates a finer thread. You will see threads labeled as 50wt. (weight) or 50/2, where the 2 means that there are two plies twisted together. A 50/2 thread is thinner than a 30/2.

In the fixed length system, the length is set and the weight is the measurement taken. In this system, a higher number denotes a heavier thread. The units of measurement are denier and tex.

- Denier is the thread's weight in grams per 9,000 meters

- Tex is the thread's weight in grams per 1,000 meters

Thread Finishes: Enhancing Performance and Aesthetics

Thread finishes include any process threads go through that changes the original characteristics. Finishes are used to improve sewability or achieve a functional requirement of the thread. They can also improve the aesthetic quality of your thread by adding luster or increasing dye fastness.

- Lubricating: Fabric safe silicone thread coating to reduce friction between needle and thread; prevents wear and prevents melting or snapping; used on all machine sewing threads

- Bonding: Coating filament thread in resin to prevent snags/breaks; increased tensile strength and resistance to mildew; common with nylon and polyester

- Glazing: Thread coated in wax, starch or other chemical to make thread stronger and smoother; not recommended for machine sewing

- Gassing: Cotton thread passed through fire at high speeds to burn off lint to produce smoother thread with brighter sheen; also called silk finish or polished cotton

- Anti-Wick: Chemical treatment that produces high resistance to water migration and yields high tensile strength and UV resistance

- Mercerization: Treated with sodium hydroxide to increase luster and strength and allows dyes to penetrate more deeply; most often used with cotton

Adjusting Thread Tension: The Why And How

Once you have chosen your thread, it's important to test the thread tension on some similar scrap fabric. Tension adjustments are necessary when changing your sewing thread, especially if there is a difference in thread thickness. You want your tension to be balanced between your needle and bobbin threads, so that your stitches lay flat. Make sure that you are also using the appropriate needle for the type of fabric you're sewing.

Sewing machines have tension knobs that can be loosened (turned to the left) or tightened (turned to the right). This knob will adjust the tension of your needle thread, but having it too tight can cause issues with your bobbin thread. Thicker threads and fabrics both typically require a higher tension setting and a longer stitch length. Thinner threads and lighter fabrics work better with a lighter tension setting and a shorter stitch length.

To adjust your bobbin thread tension on an industrial machine, take your bobbin out of the machine and grab a small screwdriver. There is a small screw on the side of a removable bobbin case, which can be adjusted slightly if you are having issues with your bobbin tension. As with the needle tension knob, turning left will loosen the tension, and turning right will tighten it.

To check if your bobbin's tension is correct, place the bobbin inside its case and hold the case up by just the thread that is coming out. If your case immediately falls, it is too loose, and if it doesn't slide down slightly when given a little pull, it is too tight.

There is also a bobbin gauge from TOWA that can be used to check your bobbin's tension. When removing your bobbin thread, use the opportunity to remove any lint or debris that may have collected underneath your needle plate during the sewing process. For home sewers, if your machine doesn't have a removable bobbin case, there should be a screw underneath where the bobbin sits to adjust.

Pro Tip: Use a permanent marker to mark the original screw position before adjusting tension and adjust in ¼-turn increments

Pro Tip: Use the same weight thread for both your needle and bobbin thread!

Now you have a better understanding of thread characteristics! Picking the right thread for your project affects not only the thread's performance in sewing machines, but also how well the stitch holds. Remember, practice makes perfect! Don't be afraid to speak to your supplier or visit your local sewing or craft store to explore your options and ask questions.